When you bite into a ripe, juicy mango, the last thing on your mind is probably how it got to your table. But behind every perfect mango is a carefully planned packaging process that preserves its freshness, protects it during transit, and ensures it reaches consumers in pristine condition.

Mango packaging is more than just boxing fruit. It’s a vital component of post-harvest handling that balances science, logistics, and visual appeal. In this post, we’ll take you through the complete journey of mango packaging—from harvest to supermarket shelves.

1. Harvesting: The First Step in Packaging

The packaging process actually begins in the orchard. Mangoes are harvested at a specific maturity stage depending on the market they’re intended for—green for export or fully ripe for local consumption. Timing is crucial. Harvesting too early can result in underdeveloped fruit, while picking too late shortens shelf life.

To prevent bruising, mangoes are typically hand-picked using clippers or poles with soft nets. They are then carefully collected into padded crates to avoid mechanical damage. These crates are the mango’s first “packaging” environment, designed to keep the fruit protected even before formal packing begins.

2. Pre-Packaging Processes

Before mangoes are boxed or wrapped, they go through several essential pre-packaging steps. These steps are vital for enhancing shelf life and preventing decay.

a. Cleaning and Washing

Mangoes are washed to remove field dirt, latex, and pesticide residues. Washing may include:

- Chlorinated water dips (to disinfect)

- Hydro-cooling (to lower the fruit’s temperature)

- Soft brushing (to clean delicate skins without damaging them)

b. Grading

Mangoes are sorted by size, weight, color, and external appearance. Grading is important not only for aesthetics but also for uniform ripening and packaging. High-end markets usually demand size and color consistency.

c. Hot Water Treatment (HWT)

To comply with quarantine regulations and prevent fruit fly infestation, many countries require HWT. Mangoes are submerged in hot water (around 46–48°C) for 30–60 minutes, depending on size. This step is mandatory for export to certain regions like the U.S. and Australia.

d. Drying and Curing

After treatment, mangoes are dried under fans and sometimes left to cure for a few hours. This stabilizes the skin and reduces moisture that might otherwise encourage fungal growth during transit.

3. Types of Mango Packaging

Mango packaging varies depending on whether the fruit is destined for domestic or international markets, the scale of production, and the level of ripeness at shipping. Let’s explore the common packaging formats:

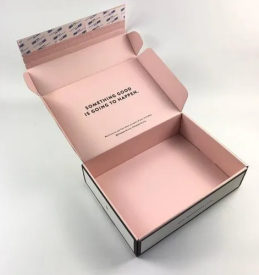

a. Corrugated Fiberboard Boxes (CFB)

These custom corrugated boxes are the most widely used packaging solutions for both local and export markets.

- Structure: Typically single- or double-walled boxes with ventilation holes.

- Sizes: Standard export box holds 4–6 kg of mangoes.

- Advantages: Lightweight, recyclable, and customizable for branding.

- Use Case: Ideal for sea or air freight. Prevents compression damage and facilitates airflow.

b. Wooden Crates

Still used in some local markets, wooden crates are sturdy and reusable.

- Pros: High strength and stackability.

- Cons: Heavy and less hygienic than modern alternatives.

- Use Case: Limited to short-distance transport or wholesale markets in some regions.

c. Plastic Crates

Reusable plastic crates are gaining popularity due to their durability and easy cleaning.

- Features: Ventilated design, smooth interiors, stackable.

- Benefits: Better hygiene and sustainability compared to one-time-use packaging.

- Use Case: Often used in closed-loop supply chains like farms delivering directly to supermarkets.

d. Retail-Ready Packs

For supermarkets and direct-to-consumer sales, mangoes are often repackaged into smaller units.

- Formats include:

- Clamshell plastic containers (1–2 mangoes per pack)

- Net bags

- Cardboard trays with film wrapping

These are usually labeled with branding, barcodes, origin information, and sometimes QR codes for traceability.

4. Internal Packaging Components

To protect each fruit within a box, internal packaging plays a critical role:

a. Fruit Nets or Sleeves

Each mango may be wrapped in a soft foam net to cushion it from impact and prevent bruising.

b. Paper Shredding or Pulp Trays

Layered packing with shredded paper or molded pulp trays separates individual fruits and absorbs excess moisture.

c. Wax Coating or Fungicide Treatment

In some cases, a light wax coating or fungicide is applied post-harvest to reduce moisture loss and microbial decay. This is particularly common for mangoes destined for long-distance export.

5. Labeling and Branding

Professional packaging includes clear labeling that serves both regulatory and marketing purposes.

Essential Label Elements:

- Producer/Exporter name

- Country of origin

- Variety (e.g., Alphonso, Kent, Tommy Atkins)

- Weight and count

- Treatment information (e.g., Hot Water Treated)

- Barcodes or traceability codes

For premium mango brands, visually appealing packaging and storytelling elements—like origin stories or farmer features—can influence consumer choice and justify a higher price point.

6. Cold Chain Management

Once packed, mangoes must be kept in controlled conditions throughout transport. This is where cold chain logistics comes into play.

- Pre-cooling: After packing, mangoes are often pre-cooled to around 10–13°C to remove field heat.

- Refrigerated Storage & Transport: To prevent premature ripening and decay, mangoes are transported in refrigerated trucks or containers with humidity control.

- Ripening Chambers (Optional): At the destination, mangoes may be ripened in ethylene chambers before reaching stores, depending on market requirements.

Maintaining an unbroken cold chain is critical, especially for export-grade mangoes. Any temperature spike can accelerate ripening and spoil the fruit.

7. Sustainability Trends in Mango Packaging

As consumers grow more eco-conscious, the mango industry is responding with sustainable packaging innovations:

- Biodegradable trays and films

- Compostable stickers and labels

- Reduction of plastic use in retail packs

- Reusable crate systems for local supply chains

Sustainability doesn’t just reduce environmental impact—it can also enhance brand reputation and open doors to premium retail markets.

8. Challenges in Mango Packaging

Despite technological advances, packaging mangoes still comes with its fair share of challenges:

- Delicate Skin: Mangoes bruise easily, requiring soft-touch handling.

- Ethylene Sensitivity: Mangoes emit ethylene gas, which accelerates ripening—not ideal during long hauls.

- Varying Sizes and Shapes: Uniform packaging is tricky when dealing with natural variation in fruit.

Proper training, innovative materials, and continuous monitoring are key to overcoming these obstacles.

Conclusion

Mango packaging is a complex but fascinating process that combines agricultural best practices, logistics, and consumer preferences. From handpicking on the farm to stacking boxes in supermarkets, every step is designed to protect flavor, freshness, and appearance.

Understanding how mangoes are packaged helps us appreciate the effort that goes into delivering this beloved tropical fruit from orchards around the world to your local grocery store. The next time you pick up a mango, take a moment to consider the journey it took—and the thoughtful packaging that made it possible.