In the world of packaging, it’s often the finish that makes the first impression. Whether we’re designing custom boxes, product labels, or marketing collateral, the type of coating we choose—glossy or matte—plays a vital role in how a brand is perceived. It’s more than just aesthetics; coatings protect, enhance, and define the feel of the packaging.

At Dotline Packaging, we help businesses like yours navigate these subtle, yet impactful decisions. In this post, we’re breaking down the difference between glossy and matte coatings, their pros and cons, and how to choose the right one for your product.

What Are Coatings and Why Do They Matter?

Coatings are applied to printed packaging surfaces to serve two main purposes: protection and visual enhancement. Think of it like putting a case on your phone. Yes, it’s for protection—but it also says something about your style.

A well-chosen coating helps:

- Protect against scratches, fingerprints, and moisture

- Make colors pop or mute them for a subtle effect

- Add texture and tactile experience

- Influence how consumers perceive the value of your product

And in a saturated market, those details can be game changers.

Glossy Coating: Bold, Bright, and Eye-Catching

Glossy coatings are like the extroverts of the packaging world. They shine, literally. These coatings add a slick, reflective surface that enhances color vibrancy and creates a smooth, almost wet-looking finish.

Pros of Glossy Coatings:

- High Color Contrast: Gloss finishes amplify color richness, making your graphics and logos stand out.

- Sleek Appearance: They offer a polished, modern look that screams premium, especially in industries like cosmetics, electronics, and luxury accessories.

- Protection: Gloss coatings provide solid protection against moisture and dirt. They’re easier to wipe clean, too.

- Cost-Effective: Standard gloss coatings are typically more affordable than specialty finishes, while still delivering high impact.

Cons of Glossy Coatings:

- Glare: In bright lighting or under spotlights, gloss can produce glare, making it harder to read fine print.

- Fingerprints: The reflective surface shows smudges and fingerprints more easily.

- Less Tactile: If you’re looking for texture or a matte feel, gloss won’t deliver that subtle touch.

Best For:

- Vibrant product packaging

- Retail displays

- Promotional materials with strong imagery

- Brochures and catalogs with lots of photography

Matte Coating: Elegant, Soft, and Understated

If glossy is bold, matte is sophisticated. Matte coatings provide a flat, non-reflective finish that feels soft to the touch and gives packaging a more refined, natural look.

Pros of Matte Coatings:

- Soft Finish: Matte feels velvety and upscale, ideal for luxury brands that want to project elegance and exclusivity.

- Non-Reflective: Easy to read under any light, matte coatings reduce glare—great for text-heavy packaging.

- Minimalist Appeal: Matte has a timeless quality, making it a favorite for high-end food, fashion, and wellness products.

- Less Prone to Smudging: Matte doesn’t show fingerprints as easily as gloss.

Cons of Matte Coatings:

- Subdued Colors: Without the shine, colors appear softer and slightly muted. This can be either a strength or a drawback depending on your design.

- Less Durable: While matte coatings are protective, they can be more prone to scratching and scuffing over time.

- Higher Cost for Specialty Effects: If you want a soft-touch matte or a textured matte finish, it can increase production costs.

Best For:

- Luxury and boutique brands

- Eco-friendly or minimalist packaging

- Text-driven designs

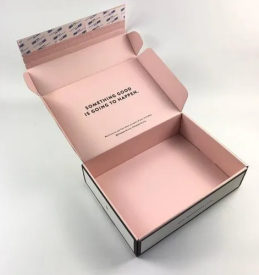

- Subscription boxes and premium gift sets

Comparing Side by Side: Glossy vs. Matte

| Feature | Glossy Coating | Matte Coating |

|---|---|---|

| Appearance | Bright, shiny, reflective | Soft, subtle, non-reflective |

| Color Impact | Boosts color intensity | Mutes colors slightly |

| Texture | Smooth, slick feel | Soft, velvety touch |

| Glare | Can be high under direct light | No glare, easier to read |

| Durability | Highly resistant to moisture | Can scuff or scratch over time |

| Branding Style | Bold, dynamic, modern | Sophisticated, calm, understated |

| Cost | Generally cost-effective | Slightly more expensive for upgrades |

What About Combining Both?

Good news: you don’t have to choose just one.

Some of the most eye-catching packaging designs use a mix of glossy and matte finishes to create contrast and focus. This technique—often called spot UV or spot varnish—applies a glossy coating to specific areas (like a logo or image) while leaving the rest matte. The result? A tactile, visual pop that draws the eye without overwhelming the design.

It’s a great way to highlight key elements while maintaining a sophisticated aesthetic.

How to Choose the Right Finish for Your Brand

Here are a few questions we always ask our clients to help guide their decision:

- Who is your target audience?Gloss tends to attract younger, more trend-driven buyers. Matte appeals to premium, boutique, and eco-conscious shoppers.

- Where will the product be sold?Retail shelves with bright lights might expose too much glare on glossy surfaces. For online-only packaging, that’s less of a concern.

- What kind of message do you want to send?Gloss is loud and proud. Matte is quiet confidence. Both can be premium—but they speak in different tones.

- What’s your color palette?If you’re using rich, vibrant colors, gloss will amplify them. If your design is minimal and elegant, matte complements that mood.

Final Thoughts

In packaging, the finish is more than just an afterthought. It’s a strategic choice that influences consumer perception, shelf appeal, and even the unboxing experience. Whether you go glossy, matte, or a combination of both, the goal is to align your packaging with your brand story and audience expectations.

At Dotline Packaging, we’re here to help you make that choice with confidence. From design consultation to final production, we offer a wide range of coating options to help your packaging shine—or stay elegantly understated.