Whether it’s healthcare, construction, logistics, arts, packaging, or any other industry, tape is an essential and the most common tool found everywhere. Though it seems like a simple product and is only for adhesion functions, it has numerous uses and endless varieties to fulfill unique functions in different industries. Do you want to explore the most famous, trending, and useful types of tapes in the market? Stick to this detailed blog post.

This piece of writing covers everything, from the general types of tape used in different industries to the most famous options used specifically in the custom printing and packaging sector. So, don’t delay! Scroll down and let’s begin.

6 Durable & Functional Tapes, Highly Demanded & Used in the Custom Packaging Industry

1- Custom-Printed Packaging Tape – The Affordable Branding Tool

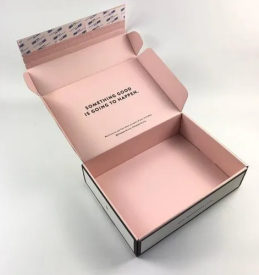

It’s a premium-quality adhesive tape, highly used for sealing boxes, cartons, or parcels featuring a brand’s logo, message, or exclusive design. It means it not only seals and secures the packaging but also helps in a brand’s effective marketing. Hence, it’s a dual-purpose tool for businesses. When it comes to manufacturing, custom-printed packaging tape is made up of a BOPP backing material, PVC, and eco-friendly Kraft materials. Its adhesive types include hot melt adhesive, acrylic adhesive, and high-grade water-activated adhesives.

Areas where Custom-Printed Packaging Tape is Highly Used

- E-commerce

- Retail

- Food & beverage

- Apparel & fashion

- Electronics, and many more

2- Water-Activated Tape or Gummed Tape – 100% Secure, 100% Recyclable

This advanced tape type is a paper-based option that is activated by water. Once moistened, the adhesive bonds permanently to the surface of corrugated boxes, creating a strong, tamper-evident seal. Usually, this tape is made up of natural brown or white Kraft paper that ensures the recyclability and biodegradability of the tape. Dextrin or starch-based glue works as adhesive layers in gummed tapes.

Industries Greatly Demanding Water-Activated or Gummed Tapes

- Luxury or high-end brands

- Eco-friendly businesses

- Food & meal delivery

- Lifestyle brands

- Pharmaceutical and medical companies

3- Hot Melt Packing Tape – More Slick, Less Slip

It’s a pressure-sensitive adhesive tape, preferably used for sealing corrugated boxes and cartons. Brands mostly use it for high-volume packaging operations. Unlike acrylic tapes, hot melt tape is made using synthetic rubber-based adhesives that provide instant, aggressive tack, excellent holding power, and fast sealing performance. It’s called hot melt because the adhesive is applied to the tape backing in a molten state during manufacturing, then cooled and solidified to form a strong, sticky bond that activates with light pressure.

Top Places Where Hot Melt Packing Tape is Majorly Used?

- Warehouses

- Fulfillment centers

- Logistics and distribution areas

- Manufacturing & industrial packaging

4- Tamper-Evident Tape – 1st Line of Defense Against Package Tampering

It’s a specialized adhesive tape, highly used to deter tampering by making unauthorized access obvious, enhancing custom package security during transit and storage. Tamper-evident tape is one of the best solutions to protect brand integrity and boost customers’ trust. The key components of tamper-evident tape include a PET, polypropylene, or laminated film backing material, and a pressure-sensitive or heat-activated adhesive layer. Void, destructible, color transfer and holographic tapes are some of the most famous types of tamper-evident tapes.

Industries Preferably Using Tamper-Evident Tapes

- Healthcare

- Pharmaceutical

- E-commerce & Shipping

- Electronics

- Retail

- Food, and many more.

8 Game-Changing General Tape Types Used in Different Industries

1- Pressure-Sensitive Tape – No Heat, No Mess, Just Instant Stick

It is one of the most common tape types used across all sectors of the e-commerce and retail industries. Just a light pressure is required to firmly apply this high-end tape to different surfaces. No heat or water is required to activate the adhesive used in pressure-sensitive tape. Masking tape, duct tape, double-sided tape, packing tape, and electrical tape are the subtypes of this common tape type.

Famous Applications of Pressure-Sensitive Tape

- Packaging

- Insulation

- Masking during Painting

- Quick Repairs

2- Masking Tape – No More Peeling Walls!

In contrast to other tape types, masking tape is a lightly adhesive and easy-to-tear tape. It is primarily used in painting and surface protection. Its main purpose is to conserve the visual appeal of the surface by ensuring its durability and quality for a long time. The famous subtypes of masking tape include painter’s tape and high-temperature masking tape.

Common Industries where Masking Tape is Use

- Painting

- Woodworking

- Automotive refinishing

3- Duct Tape – The King of Quick Fixes!

Offering a remarkable combination of strength, flexibility, and adhesion, duct tape is the widely used option all around the world. It is applicable on versatile surfaces and is strong enough to hold different weights. Duct tape is weather-resistant and very easy to be used and applied by people. It ensures durable quick repairs, bundling, securing, and efficient emergency repairs in no time.

Area of Application of Duct Tape

- Construction works

- HVAC Sealing

- General repairs

- Wall patching

- Common fixing

4- Electrical Tape – The #1 Tape Every Tool Box Needs

It is one of the famous types of pressure-sensitive adhesive tapes. As the name indicates, electrical tape insulates and protects electrical wires and other conductive materials from damage. It hinders electrical current from accidentally passing to other wires, people, and surfaces. This makes it an essential element in any electrical system. A PVC backing material and a rubber-based pressure-sensitive adhesive are typically used in making the best quality electrical tapes.

Top Applications of Electrical Tapes

- Insulation

- Safety

- Wire bundling

- Safety Marketing

- Color coding

5- Double-Sided Tape – Stick Smarter, Not Harder!

Featuring durable adhesive layers on both sides, double-sided tape professionally sticks two surfaces together without showing itself. Hence, it is ideal for invisible mounting, professional presentation, and lasting adhesion. Its backing/carrier layer includes durable foam, PVC, PET, and PE films. Sometimes no carrier is installed as well. However, the pressure-sensitive acrylic, rubber, or silicon adhesive layer is present on both sides of the tape.

Renowned Applications of Double-Sided Tape

- Signage

- Point-of-Purchase displays

- Carpet installation

- Home Craft

- Office use

6- Foam Tape – The Tape that Sticks, Seals, and Cushions

It’s a type of double or single-sided adhesive tape, made from a high-quality foam core. Specifically designed to cushion, seal, insulate, and bond to surfaces, foam tape is made up of a foam core backing and acrylic or rubber adhesive layer. It is soft but strong, just perfect for professional sealing, spacing, and damping. This tape is incredibly versatile and is used across many industries and applications. The popular industries include construction, home, automotive, electronics, packaging, and printing.

Premium-Level Applications of Foam Tape

- HVAC systems

- Glass panel mounting

- Automotive parts bonding

7- Gaffer Tape – More Grip, No Gunk!

This high-end tape is a heavy-duty, cloth-based, pressure-sensitive adhesive, standing out for a strong and reliable hold on different surfaces. It’s heat resistant and easy-to-tear by hand. The best part, gaffer tape doesn’t leave any sticky residue behind when removed from the surface. In contrast to duct tape, gaffer is a stronger, cleaner, and more professional option. Its backing material is a durable yet flexible cloth with matte coating and the adhesive part includes a rubber-based, pressure-sensitive layer.

Famous Industries that Rely on Gaffer Tape

- Film and television production

- Photography studios

- Live events and concerts

- Theater and Stage Management

- Broadcast and AV Installation

- Trade Shows and Exhibits

8- Medical Tape – A Must-Have in Every First-Aid Kit

It’s a specialized adhesive tape, used to secure bandages, dressings, medical devices, and tubing to the skin. Backing with a flexible strip or fabric, the medical tape is designed to be gentle, breathable, hypoallergenic, and safe for prolonged skin contact. This high-end and functional tape often features acrylic, silicon, or rubber-based adhesives for secure and lasting stickiness to different surfaces.

Common Areas Where Medical Tapes are Demanded

- Hospitals

- Clinics

- Homes

- Sports physiotherapy

- Emergency Response & Survival

Final Remarks

Well, general tapes are often used by individuals, and custom packaging tapes are overlooked most of the time. Dotline Packaging is a professional bespoke packaging supplier, offering an endless variety of custom packing and shipping tapes at affordable prices. So, contact them to ensure secure packaging for your top-quality cardboard, corrugated, Kraft, and other personalized box types.